The

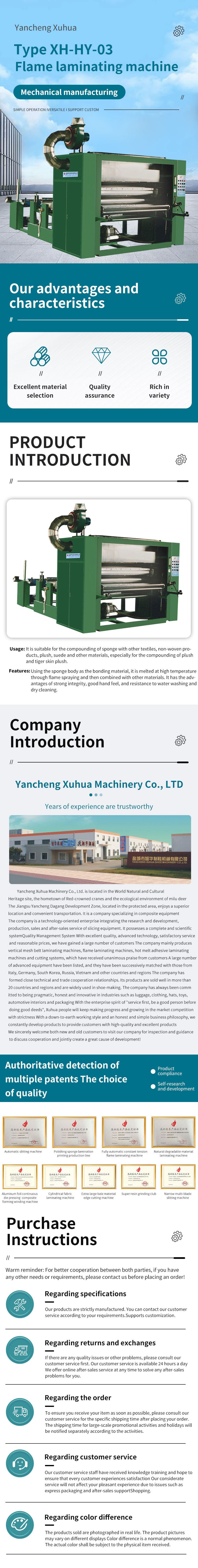

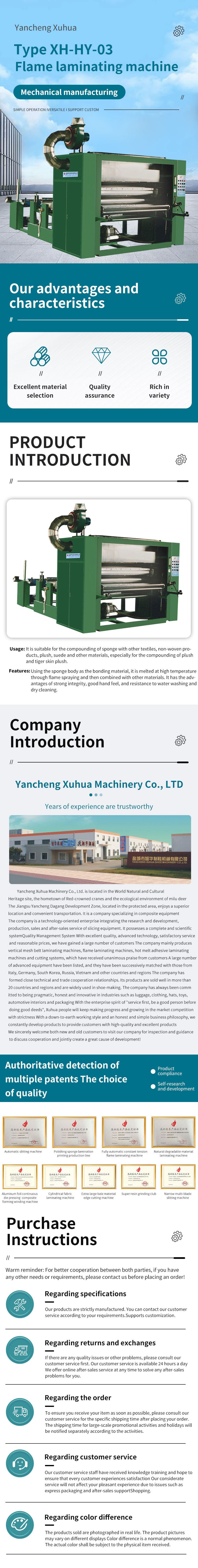

flame machine series stands as a cornerstone in modern thermal processing, designed to cater to the evolving needs of the

industry—spanning metal fabrication, construction material treatment, automotive component preheating, and heavy-duty machinery maintenance. For any

business operating in these sectors, investing in a high-quality flame machine is not just a purchase but a strategic move to enhance operational efficiency and reduce production bottlenecks. This machine integrates advanced combustion technology with precision control systems, enabling it to deliver consistent flame intensity ranging from 500°C to 1,800°C, adaptable to tasks like steel plate stress relief, pipe welding preheating, and concrete curing. Unlike traditional thermal equipment, this flame machine features an automated ignition system and real-time temperature monitoring, which minimizes human error and ensures compliance with industry safety standards (such as OSHA guidelines for thermal operations). For small and medium-sized businesses, the compact models offer portability for on-site projects, while large-scale industrial versions support continuous 24/7 operation, making them ideal for mass-production lines. In the competitive industry landscape, where speed and quality directly impact profitability, this flame machine helps businesses cut down on processing time by up to 30% compared to conventional methods. Its fuel efficiency—reducing gas consumption by 18%—also lowers operational costs, a critical advantage for businesses looking to optimize budgets without compromising performance. Whether used in a local metalworking shop or a global automotive manufacturing plant, this flame machine aligns with the industry’s demand for reliability, safety, and productivity, solidifying its position as an indispensable tool for modern business operations.