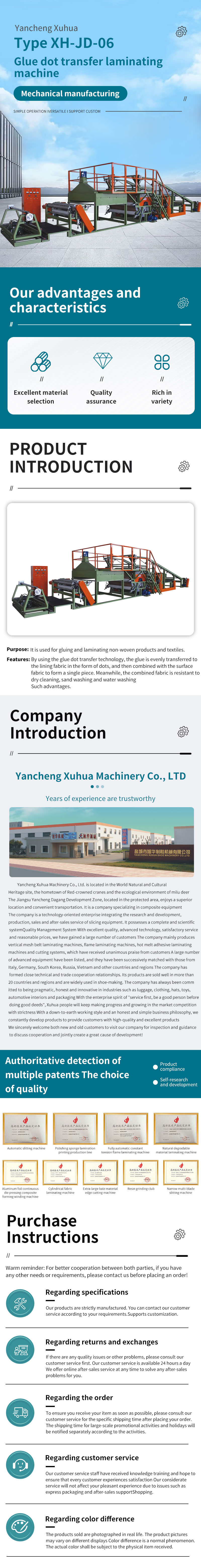

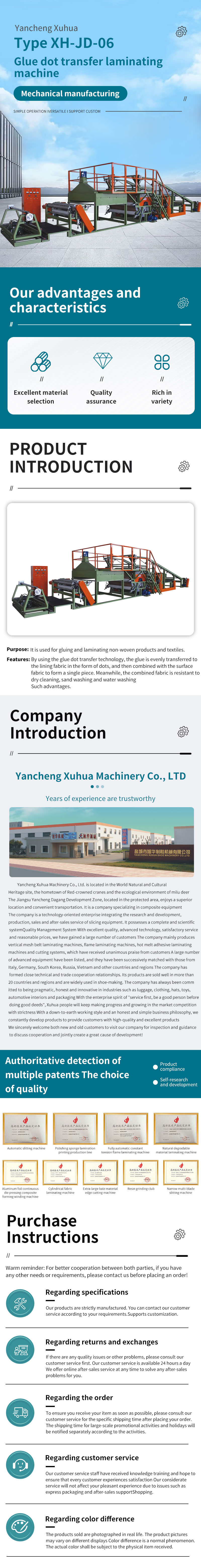

The XH - JD adhesive dot transfer machine’s outstanding performance in the

industry stems from its advanced technical specifications, tailored to meet diverse

business needs. At its core is a high - precision servo motor system with ±0.01mm positional accuracy, surpassing standard machines’ ±0.1mm. This is critical for businesses in microelectronics, where tiny component adhesive placement is vital. The servo system also achieves a dispensing speed of up to 1,500 dots per minute, supporting high - volume production. Complementing the servo motor is a high - resolution optical sensor array, detecting deviations as small as 0.005mm and triggering automatic adjustments. This eliminates manual inspection, reducing quality control time and defective products—essential in industries like medical devices. The machine’s dispensing head is modular and customizable, with nozzles from 0.05mm to 2mm for various adhesives and substrates. A heated chamber option for hot - melt adhesives maintains 50°C - 200°C ±1°C, ensuring optimal viscosity. This versatility lets businesses use one machine for multiple applications, cutting costs in the competitive industry. The control system uses a user - friendly PLC with a 10 - inch touchscreen, storing up to 1,000 programs. It also has a real - time dashboard and supports Industry 4.0 integration via Ethernet/Wi-Fi, enabling remote monitoring and data sharing. This helps businesses centralize data and optimize supply chains, key in modern digital manufacturing. Physically, the machine has a compact 1200mm×800mm×1500mm footprint, suitable for space - constrained businesses. Its heavy - duty steel frame with anti - vibration feet ensures stability and low noise (below 65 decibels). It uses 220V/50Hz power with a 3kW max draw, lower than many industrial machines, reducing utility costs and aligning with industry sustainability goals. Combining these features, the XH - JD machine delivers the performance and flexibility businesses need to thrive in modern manufacturing.