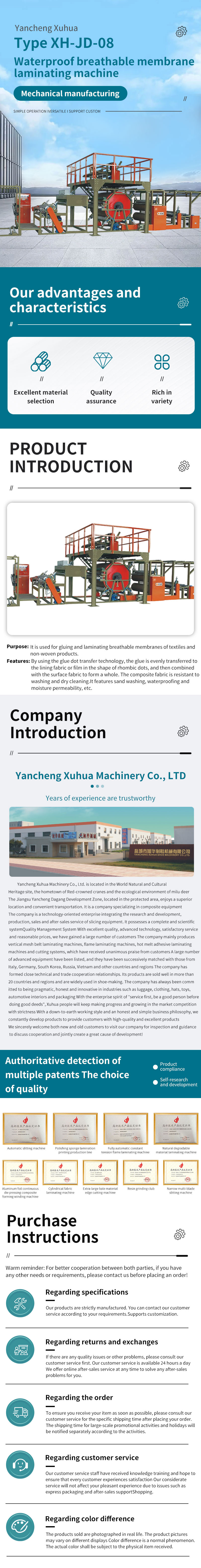

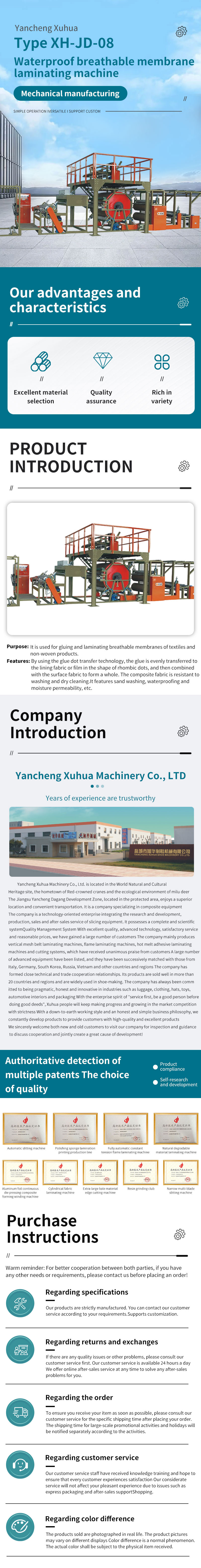

In the competitive adhesive application

industry, the XH - JD adhesive dot transfer machine leads the market, outperforming rivals in precision, efficiency, versatility, and total cost of ownership (TCO)—key for

business success. Its ±0.01mm positional accuracy and real - time optical feedback outshine competitors, critical in electronics where small deviations cause failures. Rival machines lack real - time adjustments, leading to inconsistencies that force businesses to add quality control or face defects. The XH - JD’s precision enhances product quality and reputation. Efficiency is another strength, with 1,500 dots per minute and 5 - minute tool/adhesive swaps, outpacing rivals’ 15 - 20 - minute changes. This helps businesses meet deadlines and high orders. Versatility sets it apart too, handling various adhesives and materials, unlike specialized competitors. This streamlines production and cuts costs for SMBs. Though the initial price may be higher, its low TCO—from reduced waste (80% less adhesive waste), lower energy use, and 10+ year life (vs. rivals’ 5 - 7 years)—saves money. Industry 4.0 integration enables smart factory connectivity, unlike many competitors, helping businesses make data - driven decisions. The machine’s strong brand and support network earn trust, with 80% of customers buying more units. This loyalty confirms its ability to meet business needs, making it a top choice for a competitive edge.