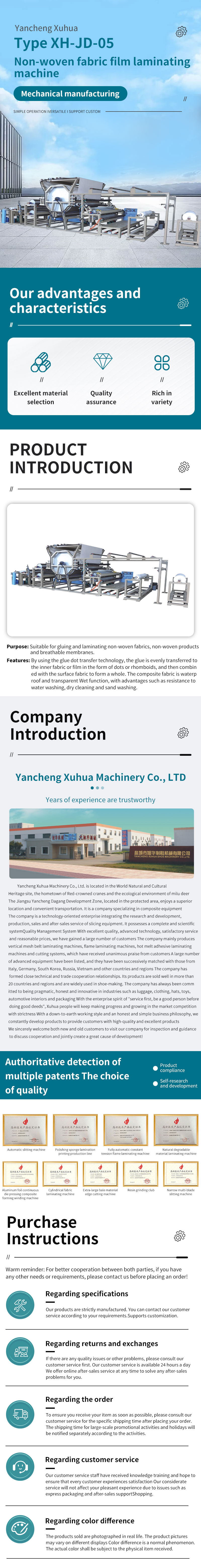

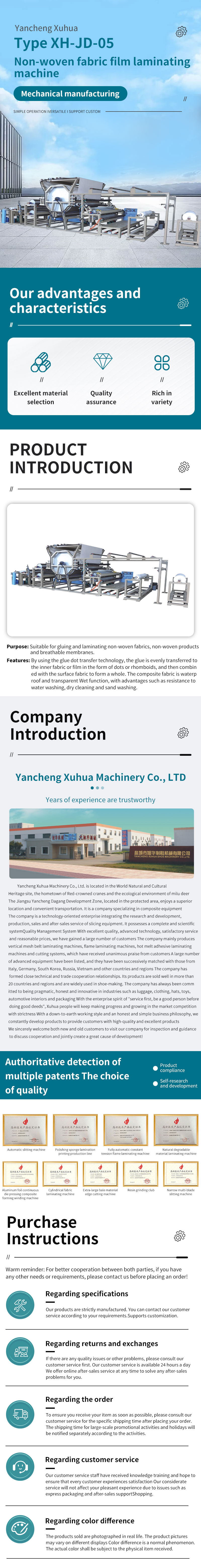

For businesses in the adhesive application space, investing in the XH - JD adhesive dot transfer machine is a strategic move that directly impacts operational efficiency, cost management, and market competitiveness—key to long - term success in the

industry. A major benefit is reduced operational costs, starting with material waste. Traditional machines waste 5 - 10% of adhesive, but the XH - JD machine’s precision cuts waste by up to 80%, lowering material and disposal costs. This also helps businesses reduce their environmental footprint, aligning with industry sustainability trends. Labor cost savings are another highlight. Manual adhesive application is time - consuming and error - prone, but the XH - JD machine’s full automation runs continuously with precision, allowing businesses to reallocate labor to value - added tasks. For high - volume production, this boosts labor productivity by 30 - 40%, a crucial gain in the competitive manufacturing industry. Beyond cost savings, the machine enhances a

business’s ability to meet customer demands and deadlines. Its quick - change dispensing heads switch between adhesive types or patterns in minutes, enabling businesses to respond fast to short lead times and custom orders. This agility is especially valuable for small to medium - sized businesses (SMBs) without multiple production lines. The machine’s reliability is also key, with a mean time between failures (MTBF) of over 5,000 hours, minimizing unplanned downtime. Its modular design allows easy maintenance, ensuring quick production resumption. For businesses with variable demand, its scalability without efficiency loss is invaluable. Additionally, the XH - JD machine provides data - driven insights via its monitoring system, tracking metrics like speed and accuracy. This helps businesses identify bottlenecks and optimize workflows, staying agile in the evolving industry. In short, the XH - JD machine is a strategic partner, helping businesses cut costs, boost productivity, enhance flexibility, and ensure reliability for long - term success in the adhesive application industry.