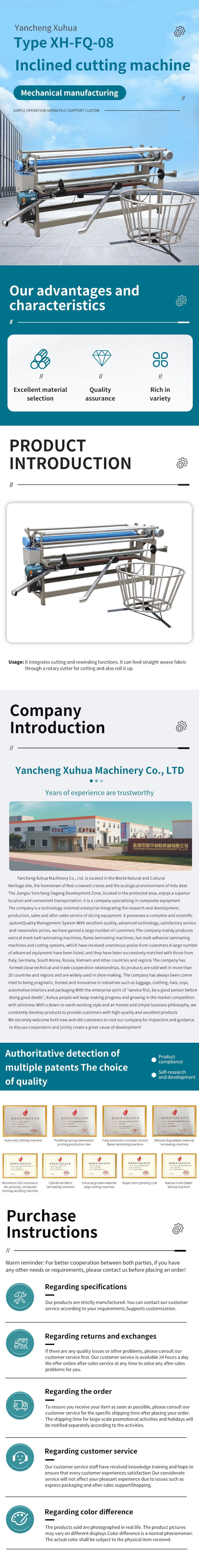

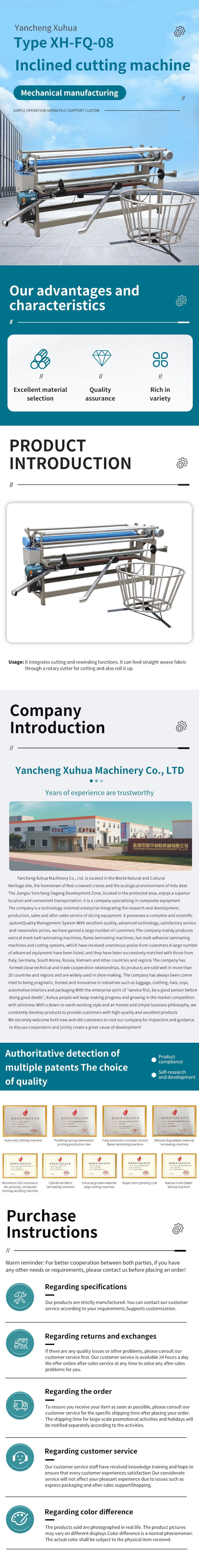

In the fast-paced packaging

industry, where efficiency and precision directly impact a

business’s profitability, the general-purpose slitting machine stands as a cornerstone of production lines. This versatile machine is engineered to handle a wide range of packaging materials, including plastic films, paper rolls, and laminated substrates, making it an indispensable asset for small-to-medium enterprises (SMEs) and large-scale manufacturers alike. Equipped with advanced PLC control systems, the machine ensures accurate slitting widths—with a tolerance as low as ±0.1mm—and high running speeds of up to 300 meters per minute, significantly reducing production cycles and minimizing material waste. Unlike traditional manual cutting methods, this automated slitting machine eliminates human error, ensuring consistent quality across every roll, which is critical for businesses aiming to meet strict industry standards such as FDA regulations for food packaging or CE certifications for global markets.

The machine’s design prioritizes ease of operation and maintenance, featuring a user-friendly touchscreen interface that allows operators to adjust parameters (e.g., slitting width, tension control, and roll diameter) in real time. Its durable construction, with high-grade steel frames and wear-resistant blades (available in high-speed steel or tungsten carbide), guarantees a long service life, reducing downtime and replacement costs for businesses. Additionally, the machine integrates automatic web guiding and edge-trimming functions, which further enhance precision and reduce scrap rates to less than 2%—a key advantage for businesses looking to optimize material usage and lower operational expenses. In the competitive packaging industry, where consumer demand for customized packaging continues to grow, this slitting machine’s ability to adapt to different material thicknesses (from 0.01mm to 1mm) and roll sizes (up to 1800mm in diameter) makes it a flexible solution that can grow with a business. Whether producing packaging for food, cosmetics, or electronics, this slitting machine ensures that businesses can meet market demands efficiently, maintain product quality, and stay competitive in an ever-evolving industry.