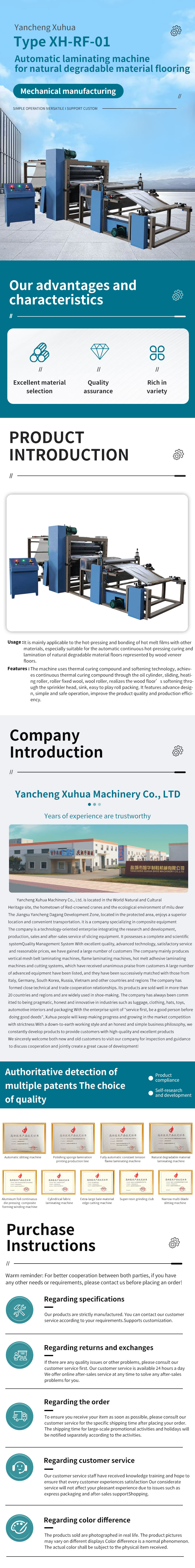

In today’s dynamic manufacturing landscape, the right machine can mean the difference between a

business thriving or falling behind—and the XH-RF Thermal Cladding Machine Series is engineered to keep businesses at the forefront of the

industry. This series addresses one of the biggest challenges facing the cladding industry: the need to balance high-quality results with cost-effectiveness. The XH-RF machine achieves this by leveraging RF heating’s inherent efficiency, which consumes up to 30% less energy than conventional infrared or flame-based cladding systems. For businesses operating in energy-intensive sectors like construction equipment manufacturing or pipe production, this energy savings translates to significant long-term cost reductions, improving profit margins while reducing environmental impact. Additionally, the XH-RF machine’s modular design allows for easy integration into existing production lines, eliminating the need for costly facility overhauls—a key benefit for businesses looking to upgrade without disrupting ongoing operations. The machine’s robust construction, using high-grade steel and wear-resistant components, ensures a service life of over 10 years with minimal maintenance, further lowering total cost of ownership. Across the industry, from automotive aftermarket parts to industrial valve manufacturing, the XH-RF series has proven its ability to meet diverse business needs, delivering cladding thicknesses ranging from 0.1mm to 5mm with unparalleled accuracy. By combining efficiency, durability, and flexibility, the XH-RF Thermal Cladding Machine Series empowers businesses to elevate their product quality and stay ahead in a competitive industry.