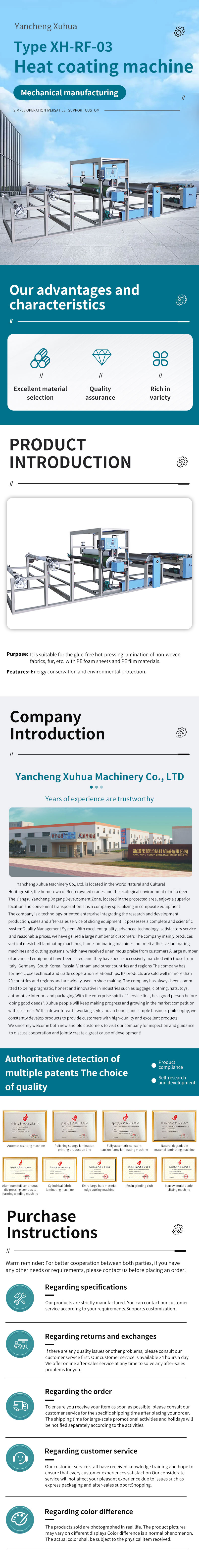

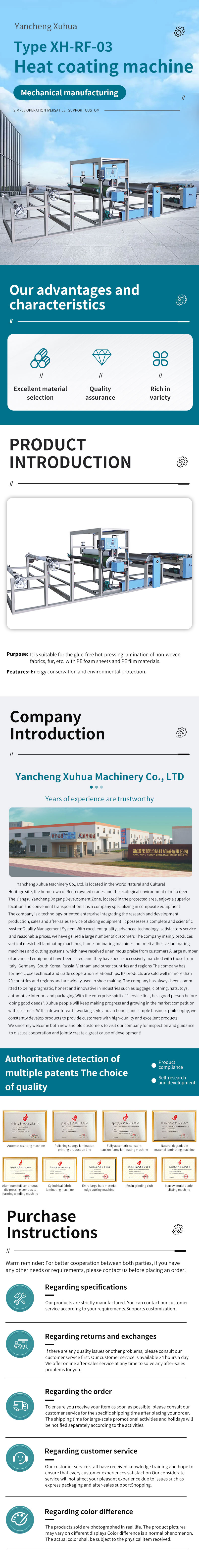

The XH-RF Thermal Cladding Machine Series is not just a piece of equipment—it’s a strategic investment for any

business looking to expand its capabilities in the cladding

industry. This machine is specifically designed to handle the unique demands of high-volume production, making it ideal for businesses in sectors like consumer electronics (where small, precision parts require consistent cladding) and white goods manufacturing (where large surfaces need corrosion-resistant coatings). One of the standout features of the XH-RF machine is its advanced temperature control system, which maintains heating temperatures within a ±2℃ range—critical for ensuring that cladding materials bond securely to substrates without causing warping or damage. This level of precision is unmatched by many competitors in the industry, allowing businesses to produce high-quality products that meet strict industry standards, such as ISO 14922 for metal cladding or ASTM D3359 for adhesion testing. The machine also includes a real-time monitoring system that tracks key performance metrics, such as heating time, cladding pressure, and material usage, providing businesses with valuable data to optimize production processes and reduce waste. For example, a business manufacturing agricultural machinery parts reported a 25% reduction in material scrap after switching to the XH-RF series, thanks to the machine’s precise material deposition capabilities. Furthermore, the XH-RF machine’s compatibility with both manual and fully automated operation makes it suitable for businesses of all sizes—from small workshops with low-volume orders to large factories requiring 24/7 production. In an industry where customer demands for faster delivery and higher quality are constantly rising, the XH-RF Thermal Cladding Machine Series gives businesses the tools they need to meet these expectations and drive growth.